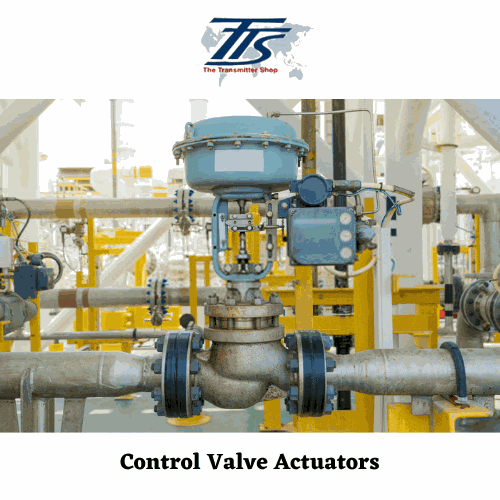

Control valve actuators play a crucial role as the driving force behind the operation of control valves. These actuators translate commands from the control system into physical movements, enabling the valve to perform its intended function. They come in various forms, powered by different energy sources such as hydraulics, pneumatics, electricity, or even manual input. Each type of actuator has unique characteristics and operational capabilities, influencing both efficiency and reliability. Understanding the different types of actuators and their potential failure modes is essential for ensuring optimal performance and longevity. This article explores the key types of control valve actuators and their associated failure modes. Actuators are compact mechanisms designed to move valve components such as plugs, balls, or vanes. When a command is sent from the control system, the actuator generates the necessary force to move the valve stem. Once the desired motion is achieved, the actuator stops functioning until the next command is issued. There are several types of actuators, each suited to specific applications: 1. Pneumatic Actuators: These actuators use compressed air to generate force. They typically consist of a diaphragm and spring assembly that responds to pressure changes. Pneumatic actuators can be configured as direct or reverse acting, depending on whether they open or close the valve when receiving an air signal. 2. Hydraulic Actuators: Similar to pneumatic actuators, hydraulic actuators rely on fluid pressure to drive movement. Instead of air, they use hydraulic fluid to push pistons within a cylinder. This results in precise and powerful motion, making them ideal for heavy-duty applications. 3. Electric Actuators: Electric actuators utilize motors to convert electrical signals into mechanical motion. They can provide either linear or rotational movement and are often used for on/off operations. With the addition of feedback loops, they can also support continuous control applications. It’s worth noting that hybrid actuators, combining elements from different types, exist to meet specific needs. Examples include electro-hydraulic and pneumatic-piston actuators. When designing actuators, engineers consider failure modes to ensure safe and reliable operation. Two common failure modes are “fail open†and “fail closed.†These modes dictate how the valve will behave under emergency or loss-of-power situations: 1. Air-to-Close Valve (ACV): In this setup, a reverse-acting actuator is paired with a reverse-acting valve body. If the air supply is lost, the valve opens automatically. 2. Air-to-Open Valve (ATO): Conversely, an ATO configuration pairs a reverse actuator with a direct valve body. Loss of air causes the valve to close. Given the critical role of actuators in valve functionality, selecting high-quality components is paramount. Trusted suppliers like The Transmitter Shop are known for providing durable and reliable products. With over 50 years of industry expertise, they offer a wide range of control valves, actuators, and process control solutions. If you’re interested in learning more about control valves, here are some relevant topics: Whether you're troubleshooting issues or exploring new technologies, these resources can help deepen your understanding of control valve systems. waders,Wading Wading Boots,Fishing Waders,Pvc Fishing Chest Wader Langfang Jinzhao Sports Products Co., Ltd , https://www.jinzhaowenti.com

Understanding Control Valve Actuators

Types of Control Valve Actuators

Failure Modes of Actuators

Additional Resources