Understanding the differences between single-phase and three-phase AC induction motors goes beyond just the power supply they use. When it comes to applications requiring instantaneous forward and reverse operations, there are several important factors to consider when using three-phase AC induction motors.

What is an Instantaneous Forward/Reverse Operation?

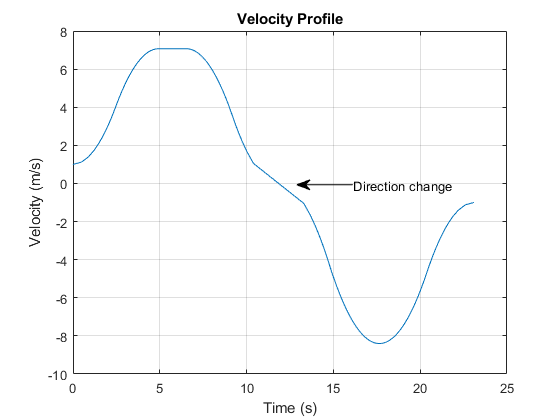

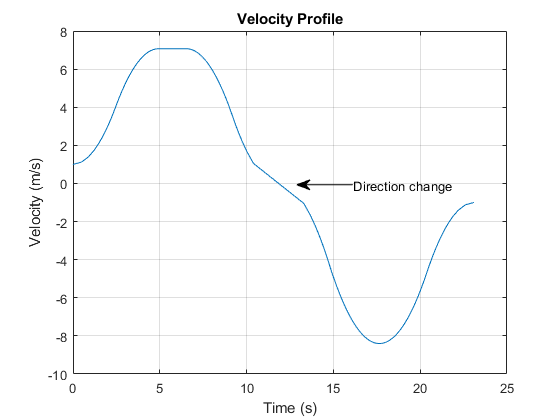

An instantaneous forward/reverse operation refers to a motor that rapidly switches between two positions repeatedly. This type of motion is commonly used in applications such as connector test fixtures, which insert and retract connectors to evaluate their reliability. While this can be achieved with AC motors, brushless motors, servo motors, or stepper motors, the key differentiator is how quickly and accurately the motor stops when commanded to halt.

Credit: Mathworks

Â

What Are the Differences Between Single-Phase and Three-Phase AC Induction Motors?

1. Winding Design

The first major difference lies in the winding design. Three-phase motors have more balanced primary and secondary windings compared to single-phase motors. This balance contributes to better performance and stability. Here's a comparison table:

Â

| Power Supply (VAC) |

Motor |

Primary Winding |

Secondary Winding |

|

| Phase U (Ohms) |

Phase V (Ohms) |

Phase W (Ohms) |

| Single-Phase 200/220/230 |

4IK25A-CW |

157.6 |

157.1 |

n/a |

| Three-Phase 200/220/230 |

4IK25A-SW |

179.9 |

179.9 |

179.9 |

Â

2. Performance and Torque

Three-phase motors typically offer higher starting torque and better speed-torque characteristics, making them ideal for applications that require quick reversals. In contrast, single-phase motors may struggle with acceleration due to lower torque output. This means that three-phase motors can reach their rated speed faster after reversing direction.

3. Starting Torque and Overrun

Single-phase motors do not stop immediately unless equipped with additional braking mechanisms. Without these, they will coast to a stop, which can cause issues in applications requiring precise control. Three-phase motors, on the other hand, have higher starting torque, allowing for quicker stops and reversals.

Â

The overrun is similar between both types once power is removed, but the higher starting torque of three-phase motors makes them better suited for instantaneous forward/reverse operations.

Â

| TIP #1: Stop a Three-Phase Motor Before Reversing Direction |

|

To ensure the longevity of your motor, it's crucial to stop it completely before reversing its direction. This helps prevent gear damage and reduces the risk of electrical short circuits.

- Gear Damage

- Risk of Power Short Circuit

Gear Damage

If you reverse the motor too quickly, the load may still be rotating in the same direction, while the motor tries to turn the opposite way. This can lead to gear damage, especially in geared motors. To reduce impact forces, it’s best to allow the motor to come to a complete stop before changing direction.

Risk of Power Short Circuit

The wiring of single-phase and three-phase motors differs significantly. A single-phase motor uses a capacitor to create a rotating magnetic field, while a three-phase motor requires a specific switch configuration to avoid short circuits. For example, a three-phase motor needs a lossless electromagnetic switch with interlock functionality to prevent simultaneous activation of two contacts.

|

Â

Brake Frequency Considerations

Brake frequency is limited by the temperature rise of the motor, which is influenced by the inrush current during startup. The more frequently the motor is cycled on and off, the higher the temperature rise. It's recommended to allow at least 2–4 seconds between cycles, depending on the motor size, to avoid overheating.

To determine the maximum brake frequency, testing is essential. For most motors, a cycle rate of 30 per minute for smaller motors (6–40 W) and 15 per minute for larger ones (60–90 W) is typical. However, exceeding these values may affect long-term performance if the temperature is not properly managed.

Â

| TIP #2: Use an Inverter for Better Control |

|

Using a variable frequency drive (VFD) allows for more precise control of three-phase motors, including instantaneous forward and reverse operations. Oriental Motor offers high-torque three-phase AC motors like the KIIS series that are compatible with VFDs.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'd411f674-af9e-49e1-ba10-30a6d710f3bc', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'd411f674-af9e-49e1-ba10-30a6d710f3bc', {"useNewLoader":"true","region":"na1"});

|

Â

Speed-torque curves below depict the expected performance of a specific motor and VFD combination.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'd9421b66-85a5-4ad3-8a78-e32e5b3602ad', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'd9421b66-85a5-4ad3-8a78-e32e5b3602ad', {"useNewLoader":"true","region":"na1"});

Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'f47582ee-d505-4674-9545-575726763a58', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'f47582ee-d505-4674-9545-575726763a58', {"useNewLoader":"true","region":"na1"});

Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'cb92d0cd-db54-498c-afe9-29756789afcc', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'cb92d0cd-db54-498c-afe9-29756789afcc', {"useNewLoader":"true","region":"na1"});

Feel free to click on the curve data above to learn more about these motors.Â

Â

Final Thoughts

Remember, an instantaneous forward/reverse operation isn't exclusive to three-phase motors. Any motor can perform this function, but the level of "instantaneity" and accuracy depends on the motor type and control method. There are always trade-offs involved in choosing the right motor for your application.

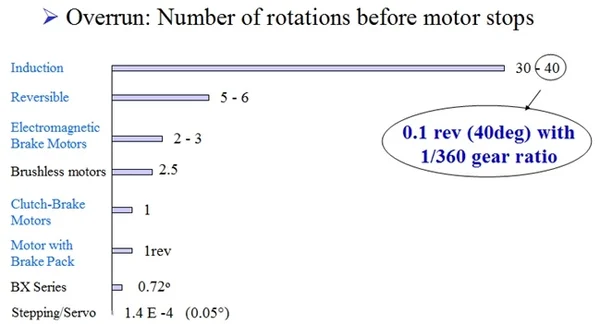

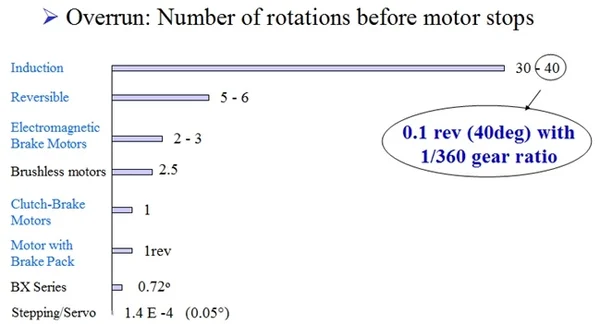

Different motor types have varying specifications regarding overrun and brake frequency. For instance, single-phase reversible motors often use friction brakes to minimize overrun, but this limits duty cycle. For high-frequency braking, electromagnetic brake motors or those with brake packs are better options.

For applications needing fast stops without strict positioning requirements, brushless motors with dynamic braking might work well. Stepper or servo motors offer the highest accuracy and starting torque, but they require more complex control systems than AC reversible motors.

Here's a comparison chart showing overrun values for various motor types. Keep in mind that these values are measured at the motor shaft, and adding a gearhead will reduce the overrun accordingly. These are reference values only.

Â

Â

Oriental Motor provides a wide range of AC induction motors from 1 W (1/750 HP) up to 2,237 W (3 HP). In addition to standard induction motors, we also offer reversible motors, electromagnetic brake motors, clutch/brake motors, and washdown motors. Gearheads can be added for high-torque applications.

Our product lines include the World K Series, which features both single-phase and three-phase motors, and the KIIS Series, known for its high torque and compatibility with VFDs. We also have the Brother Mid G3 Series for high-power applications.

On our website, we categorize our motors into "constant speed" and "speed control" types. While constant-speed motors include both single-phase and three-phase models, our "3-Phase AC Motors for VFDs" section focuses on three-phase motors designed for speed control.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e002f482-3843-4214-a9a1-685fd9604a4c', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e002f482-3843-4214-a9a1-685fd9604a4c', {"useNewLoader":"true","region":"na1"}); |

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '218d24d0-68fb-467f-8997-016acaab2b27', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '218d24d0-68fb-467f-8997-016acaab2b27', {"useNewLoader":"true","region":"na1"}); |

Please subscribe to this blog on the top right corner of the page.Â

Â

Construction Material Hoist,Vfd Construction Hoist,Sc Construction Hoist,Building Hoist,Construction Passenger Hoist

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'd411f674-af9e-49e1-ba10-30a6d710f3bc', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'd411f674-af9e-49e1-ba10-30a6d710f3bc', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'd9421b66-85a5-4ad3-8a78-e32e5b3602ad', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'd9421b66-85a5-4ad3-8a78-e32e5b3602ad', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'f47582ee-d505-4674-9545-575726763a58', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'f47582ee-d505-4674-9545-575726763a58', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'cb92d0cd-db54-498c-afe9-29756789afcc', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'cb92d0cd-db54-498c-afe9-29756789afcc', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e002f482-3843-4214-a9a1-685fd9604a4c', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e002f482-3843-4214-a9a1-685fd9604a4c', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '218d24d0-68fb-467f-8997-016acaab2b27', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '218d24d0-68fb-467f-8997-016acaab2b27', {"useNewLoader":"true","region":"na1"});