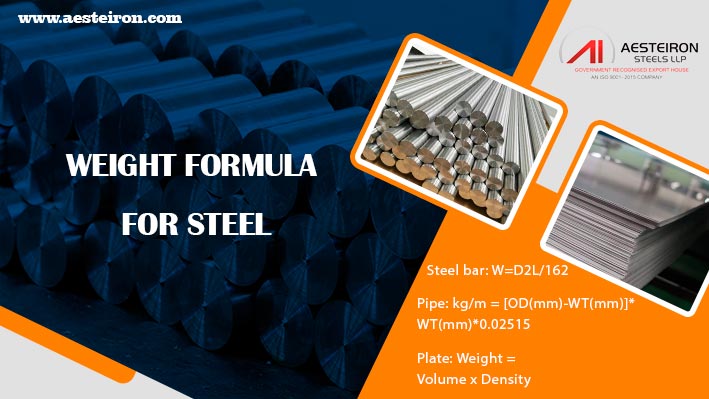

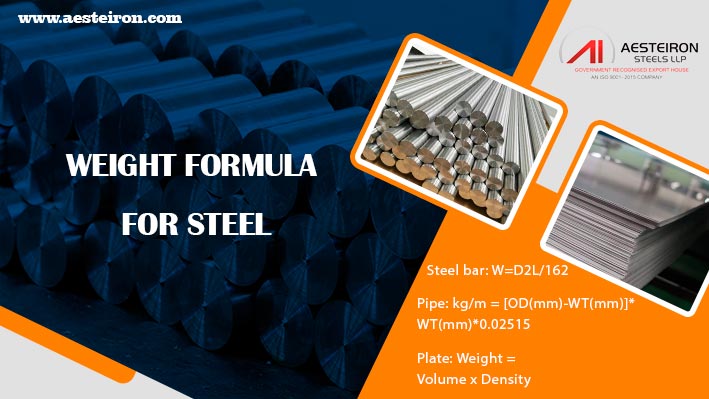

Calculating the weight of steel accurately is crucial in various construction applications. It ensures the structural integrity and safety of buildings, helping to avoid overloading. By using the correct steel weight formula, you can prevent errors that may occur during manual measurements, reducing the risk of structural failure and saving time and resources.

Table of contents

- Steel Bar Weight Chart

- Weight Chart of Bars per Bundle

- Steel Plate Weight Chart

- Weight of Steel Bars Formula

- Steel Unit Weight Per Kg

- Factors Influencing Steel Beams Weight Calculation

- Steel Pipes Weight Formula

- Steel Bars Tolerance

- Steel Types and its Density

- Steel Weight in Feet

Calculate bars and plate weight using formula

The table below provides accurate weight values for different steel sizes, making it easier to choose the right material for your project.

Steel Bar Weight Chart

| Size MM |

|

8 |

10 |

12 |

16 |

| BIS Standard KG/MTR. |

min |

0.367 |

0.574 |

0.844 |

1.501 |

| avg |

0.395 |

0.617 |

0.888 |

1.58 |

| max |

0.423 |

0.66 |

0.932 |

1.659 |

| Values Kg/Mtr. |

|

0.375 to 0.400 |

0.580 to 0.620 |

0.850 to 0.910 |

1.510 to 1.600 |

| Size MM |

20 |

25 |

28 |

32 |

|

| BIS Standard KG/MTR. |

2.396 |

3.734 |

4.685 |

6.121 |

|

| 2.47 |

3.856 |

4.83 |

6.31 |

|

| 2.544 |

3.964 |

4.975 |

6.499 |

|

| Values Kg/Mtr. |

2.400 to 2.510 |

3.750 to 3.910 |

4.700 to 4.900 |

6.184 to 6.436 |

|

Weight Chart of Bars per Bundle

| Steel Bar Size (mm) |

8 |

10 |

12 |

16 |

20 |

25 |

28 |

32 |

| Steel Bar pieces per bundle (No.s) |

10 |

7 |

5 |

3 |

2 |

1 |

1 |

1 |

| Length of Steel Bar (M) |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

12 |

| Total Weight of Steel Bar bundle (Kg) |

45 |

48.72 |

51 |

54.36 |

57.6 |

45 |

56.4 |

74.21 |

Steel Plate Weight Chart

| Plate Thickness |

(mm) |

1.6 |

2 |

2.5 |

3 |

3.2 |

4 |

5 |

6 |

8 |

10 |

12.5 |

15 |

20 |

22.5 |

25 |

30 |

32 |

35 |

40 |

| Weight |

(kg/m2) |

12.6 |

15.7 |

19.6 |

23.6 |

25.1 |

31.4 |

39.3 |

47.1 |

62.8 |

78.5 |

98.1 |

118 |

157 |

177 |

196 |

236 |

251 |

275 |

314 |

| Plate Thickness |

(mm) |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

90 |

100 |

110 |

120 |

130 |

150 |

160 |

180 |

200 |

250 |

|

| Weight |

(kg/m2) |

353 |

393 |

432 |

471 |

510 |

550 |

589 |

628 |

707 |

785 |

864 |

942 |

1051 |

1178 |

1256 |

1413 |

1570 |

1963 |

|

Check the formula to calculate weight of steel

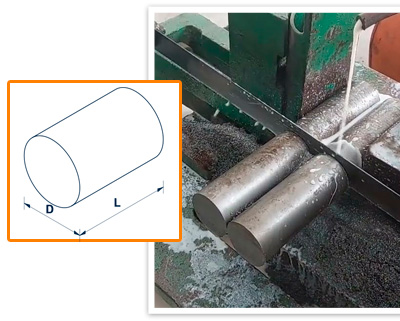

Weight of Steel Bars Formula

Steel Bars Weight = D²/162

Where,

D = Diameter

162 is a constant value

D2/162 Formula Derivation

Consider,

Diameter = D

Length = L

Weight of Steel Bar (W) = Unit Weight of Steel Bar (γ) x Volume (V)

W = γ x V

W = πD²/4 x γ (V = πD²/4)

7850 kg/m3 (γ) = Steel unit weight

W = πD²/4 x 7850

steel dia in mm

density = kg/m3

Steel diameter in mm will be converted to m to create a constant value in the same unit

D² mm / 1000²

W = π/4 x D²/1000² x 7850

W = D²/162.28 kg/m

W = D²/162 kg/m

Refer unit weight of steel per kg

The table below shows the weight of steel per meter, which is useful for construction and engineering projects.

Steel Unit Weight Per Kg

| Unit Weight Of Steel |

| Size |

6 mm |

8 mm |

10 mm |

12 mm |

16 mm |

20 mm |

25 mm |

32 mm |

| Kg/m |

0.222 kg |

0.395 kg |

0.617 kg |

0.89 kg |

1.58 kg |

2.47 kg |

3.86 kg |

6.32 kg |

View the factors which influence weight calculation of Steel Beams

Factors Influencing Steel Beams Weight Calculation

1] Beam Size and Shapes

- Dimension: thickness, width and Height

- Cross-Sectional Shape: U-beams, H-beams, I-beams etc

2] Beam Length

- If there is no change in the cross-sectional area, longer beams weigh more than shorter ones

3] Steel Grade and Density:

- Steel Type

- Beams made of higher density steel weigh more.

4] Additional Load

- Dead Loads: non-moving loads, Permanent load

- Live Loads: Temporary and varying loads

5] Connections and Joints

- The total weight is affected by the type and quantity of joints and connections

Calculate the weight of steel pipes using below formula

Steel Pipes Weight Formula

Steel pipes = W = 0.02466 x D^2 x L / 10202

Where,

W = steel pipe weight in kg/m

D = steel pipe OD in mm

L = steel pipe length in m

Eg:

Consider,

steel pipe OD (D)= 100 mm, length (L) = 6m

W = 0.02466 x 100^2 x 6 / 10202

W = 0.02466 x 10000 x 6 / 10202

W = 1480 / 10202

W = 0.145 kg/m

Steel Bars Tolerance

| Nominal Size (mm) |

|

Over 10 upto and including 16 |

Up to and including 10 |

Over 16 |

| Tolerance On |

Batch |

± 5 |

± 7 |

± 3 |

| The Nominal |

Individual Sample |

-6 |

-8 |

-4 |

| Mass, Percent |

Individual Samples for Coils Only |

± 6 |

± 8 |

± 4 |

Steel Types and its Density

| Steel type |

Carbon steel |

Tool steel |

Wrought iron |

Carbon tool steel |

Cold-drawn steel |

| Density (kg/m³) |

7840 |

7715 |

7750 |

7820 |

7830 |

| Steel type |

C1020 HR steel |

Pure iron |

Mild steel |

Stainless steel |

|

| Density (kg/m³) |

7850 |

7860 |

7870 |

8030 |

|

Steel Weight in Feet

| Size |

6 mm |

8 mm |

10 mm |

12 mm |

16 mm |

20 mm |

25 mm |

32 mm |

| Kg/feet |

0.067 kg |

0.120kg |

0.188 kg |

0.270 kg |

0.480 kg |

0.751 kg |

1.174 kg |

1.925 kg |

VAE CW40-716

Vae Emulsion Cw40-716,Sinopec Vae Cw40-716,Sinopec Vae,Sinopec Vinyl Acetate Ethylene Emulsion Cw40-716

Saint Petrochemicals Limited , https://www.saintpec.com