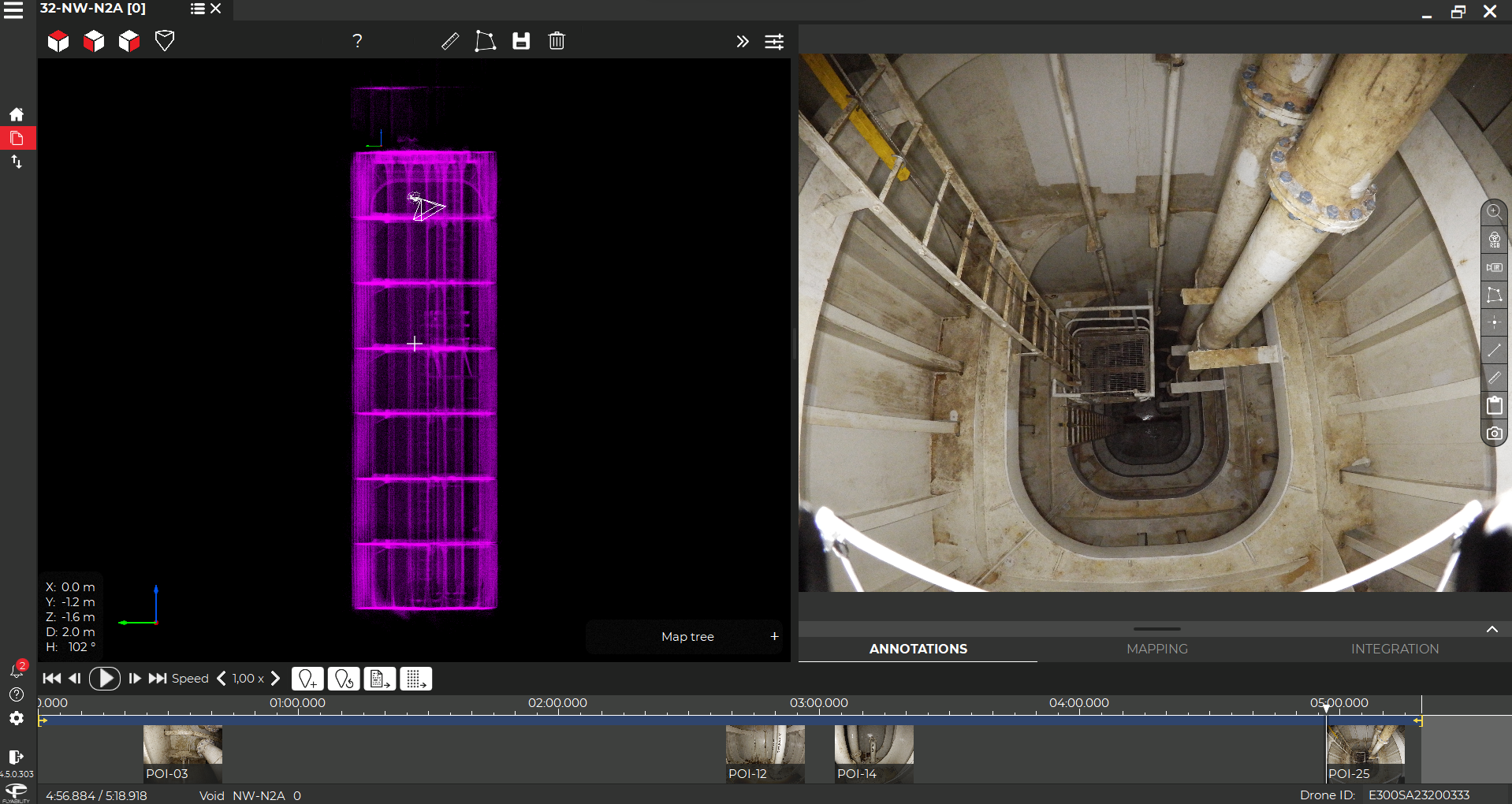

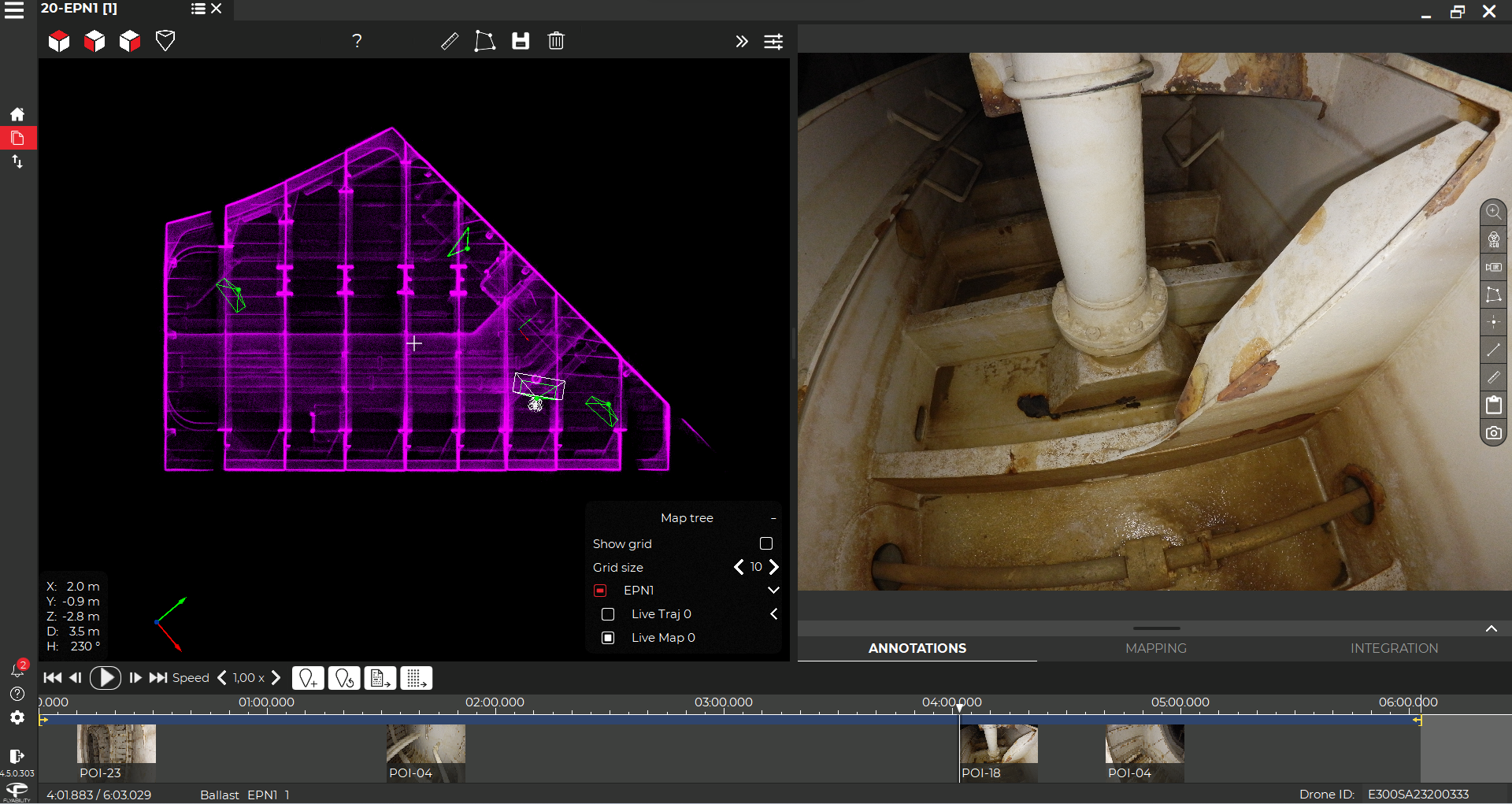

Elios drones helped TDBR Inspections transform the way they handle tank inspections at the 3R-2 offshore rig off Brazil's coast. Speed Using the Elios 2 and Elios 3, TDBR Inspections completed inspections of 63 tanks in just 14 days, with only two team members. Previously, this task would have taken months and required at least three inspectors. Safety With drones, there was no need for personnel to enter the tanks or work at heights. This eliminated the need for special permits, streamlining the entire process. Accuracy The results from these inspections were shared with the Class Society, which sets standards for maritime and drilling equipment. Every single result from the Elios 2 and Elios 3 met the required class standards. Efficiency By using drones, the number of people on board (PoB) was never exceeded, allowing the rig to be better optimized for engineers and workers instead of inspection teams.   Working offshore presents unique challenges. Equipment failures or delayed deliveries can lead to costly downtime or safety risks. Balancing inspection and maintenance with operational efficiency is crucial, especially when every square meter matters. However, inspecting critical assets like tanks can be labor-intensive and time-consuming. For 3R-2, a TLWP-type oil rig off Brazil's coast, major inspections are particularly challenging. The rig has a maximum PoB limit of around 60 people, including engineers, operators, and support staff. Transporting staff via helicopter makes optimizing the PoB count essential for smooth operations. Yet, inspecting large tanks onboard can be daunting. Each tank requires multiple staff members using ropes, taking several days per inspection. Given the rig's age and stringent regulatory standards, thoroughness is paramount. The challenge is finding a method that ensures accurate inspections without overburdening the rig with inspection teams. These tanks are tall, making manual inspections risky and inefficient. Traditional methods are slow and cumbersome. Relying on rope access teams takes too much time and resources. Moreover, special permits are often required for confined space entry, adding complexity. Could there be a faster, safer way to gather the necessary data? TDBR Inspections, a Brazilian drone services provider, specializes in complex inspections using the Elios drone. They were approached by Raul Martini, a naval engineer from 3R Petroleum, owner of the 3R-2 rig. The goal was to inspect the rig's tanks using drones and assess whether this approach could save time and effort. TDBR Inspections aimed to capture detailed visual data of the tanks, creating an image archive for future reference. Key areas of interest were flagged with paint markers for subsequent repairs. With over 70 tanks on-site, this project was ambitious. TDBR planned to visit the rig four times to collect comprehensive data. Using drones promised significant benefits, including time and cost savings, along with simplified logistics. Unlike traditional methods, drones don’t require special permits for confined space entry. Additionally, the data had to meet the rigorous standards of the Class Society. Success here could open doors for ongoing drone-based inspections across 3R Petroleum’s fleet. TDBR Inspections sent a team to 3R-2 to map out their drone flight strategy during Phase 1. They conducted preliminary reconnaissance flights with the Elios 2, scouting the tanks and planning their routes. Inside a ballast tank captured by the Elios 3.  Following initial external inspections in Phase 1, the team returned a month later to begin Phase 2. During that time, they purchased an Elios 3 and brought both drones back to 3R-2. Over two weeks, TDBR’s pilots completed 88 individual flights across 63 tanks, logging over 10 hours of flight time. Both the Elios 2 and Elios 3 were utilized. Once all flights were done, the data was processed in Inspector 4. Visual inspections from both drones updated existing records and highlighted anomalies, while the Elios 3’s LiDAR data created precise 3D models of the tanks. These models offered detailed insights into the tanks' conditions without anyone needing to enter the confined spaces. This project was unprecedented—inspecting 63 tanks in two weeks equates to inspecting over 10 assets daily. By contrast, traditional methods might require up to five rope access technicians per FSPO, taking a week per tank. With drones, two people could complete inspections in just two days per tank. Looking ahead, TDBR Inspections anticipates repeating this type of inspection at 3R-2 and other similar sites. Their efforts not only saved time and money for 3R-2’s management but also optimized staffing levels, addressing the PoB challenge. The Elios drones ensured safety, delivered accurate data, and met the strict requirements of the Class Society. This innovation has solved a pressing industry issue. Learn more about the Elios 3 and its diverse applications. Pickleball Paddle,Pickleball Rackets,Custom Pickleball Paddle,Gearbox Pickleball Nantong Zhongyi Electronic Technology Co., Ltd. , https://www.apl-pickleball.comInspecting 63 Tanks With 2 Drones In Just Two Weeks

Key Benefits At A Glance

Customer Needs: Complex Inspections On An Offshore Rig

Solution: Drone Inspections To Revolutionize Efficiency

The Elios 2 (top) and Elios 3 (bottom) prepare to enter a confined tank space.

The Elios 2 (top) and Elios 3 (bottom) prepare to enter a confined tank space.Results: Completing 63 Tank Inspections In Just 14 Days

Conclusion: A Future-Focused Approach To Rig Inspections