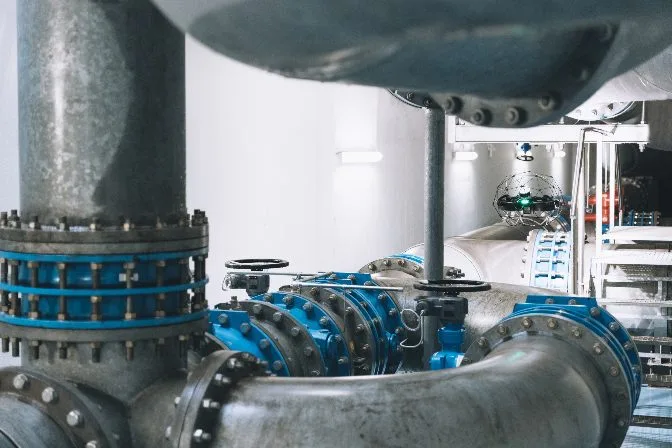

A visual inspection involves examining an asset solely with the human eye, without the aid of magnification or other specialized tools. This type of inspection doesn't necessarily require advanced equipment, but it does demand specialized training to ensure the inspector knows what to look for during the review process. Traditionally, visual inspections were performed by an inspector walking around or inside the asset, such as a boiler, to visually assess every component. However, advancements in Remote Visual Inspection (RVI) tools are now enabling inspectors to gather visual data without needing to be physically present, revolutionizing the way inspections are conducted. Some RVI tools are so sophisticated that inspectors can rely almost entirely on the visual data they collect for their assessments. [Visual inspection NDT—or visual testing—is just one of the non-destructive testing (NDT) methods that inspectors use. Learn more about NDT in this in-depth guide.] This guide provides detailed information about visual inspections, the industries that utilize them, other inspection techniques inspectors employ, and also includes insights into how drones can assist with visual inspections.  What Is the Purpose of a Visual Inspection? Visual inspections are among the oldest and most reliable methods for evaluating the condition of an asset as part of the overall maintenance process. The purpose of a visual inspection is to detect any issues that might require maintenance before they worsen. For instance, if an inspector is conducting a visual inspection of an industrial boiler's interior, they might look for cracks or buckling in the welds, corrosion on the walls, leaks, or problems with any supporting equipment. The primary goal is to address these issues early to prevent accidents. In industries like commercial inspections, missing critical issues in assets—such as a crack in a boiler—could lead to severe accidents. Therefore, visual inspections of critical assets like boilers and pressure vessels are usually carried out by licensed inspectors adhering to strict guidelines, often mandated by law. Visual inspections are utilized across every industrial sector. The reason is straightforward: visually assessing an asset with the naked eye is one of the simplest yet most effective ways to identify flaws. Here are some sectors that regularly incorporate visual inspections into their maintenance routines: If an industry employs large assets requiring regular inspections, a visual inspection is typically the first step in the inspection process. While visual inspections are the most common method, they are just one of many inspection techniques. When performing non-destructive testing (NDT), inspectors use various methods to collect data about an asset's condition without causing damage. Here are some additional inspection techniques: 1. ULTRASONIC TESTING (UT): The process of transmitting high-frequency sound waves into a material to identify changes in its properties. Learn more in this guide to ultrasonic testing. 2. RADIOGRAPHY TESTING (RT): The act of using gamma or X-rays to identify imperfections in materials. Learn more in this guide to radiography testing. 3. MAGNETIC PARTICLE TESTING (MT): Identifying imperfections in materials by examining disruptions in the magnetic field flow within the material. Learn more in this guide to magnetic particle testing. 4. ACOUSTIC EMISSION TESTING (AE): Using acoustic emissions to identify possible defects in materials. Learn more in this guide to acoustic emission testing. 5. LIQUID PENETRANT TESTING (PT): The process of coating a material with a liquid and observing breaks in the liquid to identify imperfections. Also known as dye penetrant testing. Learn more in this guide to dye penetrant testing. 6. LEAK TESTING (LT): Studying leaks in vessels or structures to identify defects. Learn more in this guide to leak testing. As mentioned earlier, visual inspections don't always require physical presence. With improvements in camera and robotics technology, inspectors are increasingly relying on RVI tools to gather visual data remotely. Inspectors prefer RVI over traditional visual inspections when the area to be inspected is hazardous or difficult to access, or both. For example, entering a mine shortly after a blast is far too risky to be done manually. Instead, a drone can be deployed to survey the area remotely, providing visual data that helps personnel decide if it's safe to enter. In less extreme scenarios, inspecting a massive oil storage tank can be dangerous due to the need to climb scaffolding erected high above the ground. Using a drone eliminates the risk of falls, allowing the inspector to stay at a safe distance while collecting the necessary visual data. Here’s how an inspector might use RVI in their workflow: As you can see, the inspector is still conducting a visual inspection, but now the inspection is conducted via data viewed on a screen rather than in person. Even home and building inspections are benefiting from remote inspections these days. Using video calling apps like Zoom or FaceTime, an inspector can conduct a virtual inspection remotely by viewing the live video feed provided by someone on-site, ensuring the inspection is completed as required. Drones aren’t the only tools for conducting RVI, though they are becoming increasingly popular. Inspectors have experimented with various confined-space tools, such as cameras dropped on ropes or mounted on robotic crawlers. However, more and more inspectors are opting for drone technology due to its superior control and quality. Drones like Flyability’s Elios 3 offer features such as oblique lighting, enabling inspectors to better visualize the depth of surfaces they’re inspecting, allowing them to understand what they’re seeing without being physically present. Here are some key advantages of using drones for remote visual inspections:  Chain Shackles are assembled together with cast pins,

working with cement kiln chains. Chain shackles are manufactured by

investment casting technology to ensure high dimensional accuracy and

surface finish. The chain shackles have the advantage of heat resistant, which make them work in the cement kiln. Standard Shackles,Cast Heat Resistant Shackles,Cast Shackles For Rotary Kiln Chain,Cast Abrasion Resistant Shackles Jilin Huanyu New Materials Manufacturing Co., Ltd , https://www.huanyufoundry.comVisual Inspections: A Complete Guide

Which Industries Utilize Visual Inspections?

Other Types of Inspections

Remote Visual Inspection (RVI)

The Elios 3 flying inside a salt mine

The Elios 3 flying inside a salt mine

Drone footage of a damaged wind turbine struck by lightning

Drone footage of a damaged wind turbine struck by lightningHow Drones Enhance Visual Inspections

The evolution of visual inspection techniques, particularly with the advent of RVI and drone technology, has transformed how inspectors approach asset evaluation. As industries continue to prioritize safety and efficiency, visual inspections will undoubtedly remain a cornerstone of maintenance practices, supported by innovative tools that enhance accuracy and reduce risks.

# A Comprehensive Guide to Visual Inspections