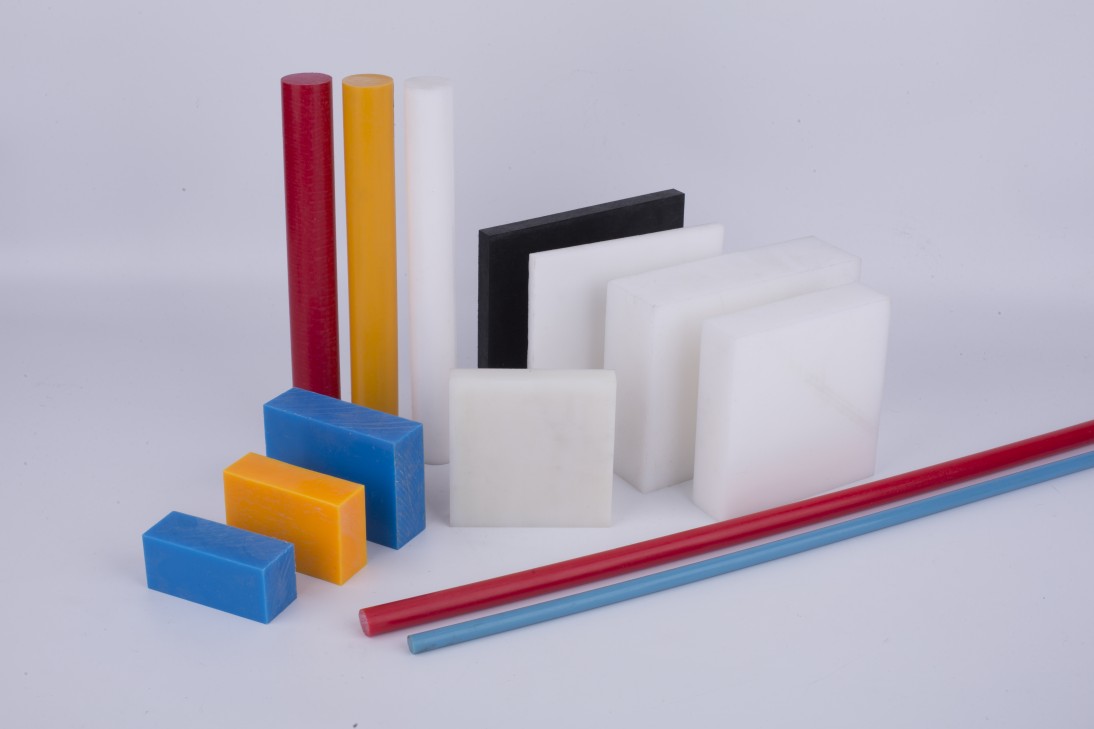

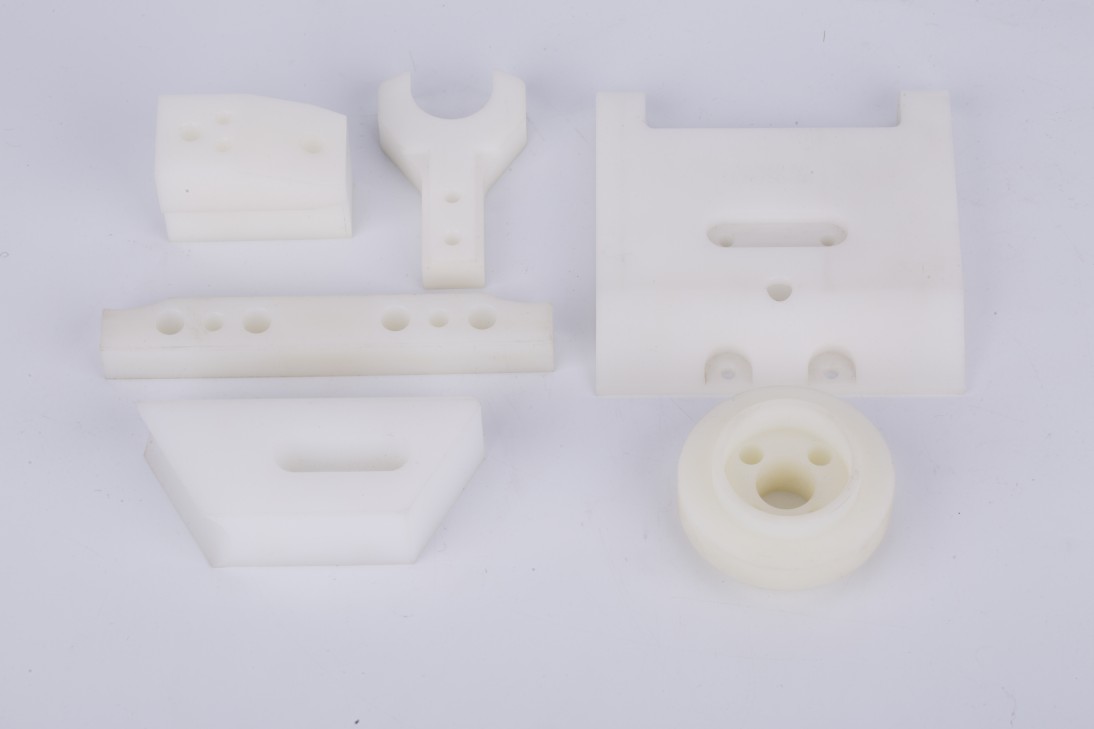

HONY®POM CNC machined Delrin is an engineering plastic ideal for parts with high stiffness, low friction and low water absorption. It is widely used in the automotive and consumer electronics industries . Acetal or POM (Polyoxymethylene) is an engineering plastic known for being amongst the strongest and stiffest of all thermoplastics. There are two general types of Acetal resins available: Acetal Homopolymer and Acetal Copolymer. Acetal homopolymer resins are made by the DuPont Company under the trade name Delrin®. Homopolymers are typically used in highly regulated industries. HONY Plastic based China is professional Pom machined Parts Manufacturer High quality precision machined components - acetal milling & turning Specialising in intricate, tight tolerance work Extensive experience and high customer satisfaction Acetal Copolymer: Absorbs very little moisture High mechanical strength and rigidity Improved dimensional stability over comparable homopolymer formulations due to the lower level of crystallinity Low coefficient of friction Good compressive strength Good shock resistance Better chemical resistance with high pH solutions Lower centerline porosity than homopolymer in extruded shapes Excellent machinability Acetal Homopolyer: Stiffer Wide operating temperature range (-40°C to 120°C) Higher flexural modulus at room temperature Higher impact strengths at room temperatures and low temperatures Tensile strength is approximately 10-15% higher than comparable copolymers Slightly higher continuous use temperature than copolymer (95°C vs. 90°C) Good compressive strength Good shock resistance Lower thermal expansion rate Better wear resistance Easy to machine POM processing Components Typical Components & Applications: Electrical insulation Medical applications Food contact components (FDA compliant) Gears Bearings Housings Fasteners Bushings Handles Seals Valves Tooling Delrin fabrication part Industry Examples: Copolymer Food & packaging Medical & pharmaceutical Automative Electrical/Electronic Agriculture Homopolymers Typically used in highly regulated industries such as: Aerospace Nuclear Pharmaceutical Pom Delrin Acetal,Pom machined Parts,delrin fabrication part,POM processing Components,Acetal,Delrin,POM machining component Hony Engineering Plastics Limited , https://www.honyplastic.com

**CNC Router CNC ATC Engraver**

**Model NO.:** VCT-2030ATC8

**Customized:** Yes

**Condition:** New

**Color:** Customizable

**Working Size:** 1300 x 2500 x 150 mm

**Spindle Power:** 9 kW, Italy HSD ATC Spindle

**Driver:** Panasonic Servo Motor Driver

**Tool Stock:** 8 or 10 Tools

**Transmission:** XY – German Gear Rack, Z – High Accuracy Ball Screw

**XYZ Guiding Rails:** PMI Square Rails

**Maxi Working Speed:** 15,000 mm/min

**Data Transmission:** Syntec Controller from Taiwan or NC Studio Control

**Format of Instructions:** G Code or HPGL

**Net Weight:** 2500 kg

**Trademark:** VICUT

**Transport Package:** Export Standard Wooden Packaging

**Specification:** CE, SGS, ISO9001, ROHS

**Origin:** Hefei, China

**HS Code:** 8458110090

**Features:**

1. Equipped with a circular automatic tool-changing system with 8/10 tools, changing tools in under 2 seconds.

2. Heavy-duty machine body with sand-filled square tubes, ensuring high stability and accuracy.

3. Uses top global brands like Italy HSD spindle, Taiwan PMI rails, Japan Yaskawa servo motor, and Taiwan Syntec controller.

4. Germany helical gear rack on the Y-axis for reduced vibration and noise during operation.

5. OEM services available to meet specific customer requirements.

**Applications:**

- **Materials:** Wood, PVC, ABS Sheet, Acrylic, Aluminum, Brass, Steel, etc.

- **Fields:** Used for furniture production (doors, windows, cabinets), acrylic letter making, and more.

**Product Specifications Table:**

| Model | VCT-1325ATC8 | VCT-1530ATC8 | VCT-2030ATC8 |

|----------------|--------------------|---------------------|----------------------|

| Machine Dimension | 2500 x 3200 mm | 3000 x 3800 mm | 3500 x 3800 mm |

| Working Size | 1300 x 2500 x 200 mm | 1500 x 3000 x 200 mm | 2000 x 3000 x 200 mm |

| Spindle Power | 9 kW (12 HP) | 9 kW (12 HP) | 9 kW (12 HP) |

| Driving Motor | Japan Panasonic | Japan Panasonic | Japan Panasonic |

| Tool Stock | 8/10 Tools | 8/10 Tools | 8/10 Tools |

| Structure | Thick steel tube | Thick steel tube | Thick steel tube |

| Transmission | Germany Gear Rack | Germany Gear Rack | Germany Gear Rack |

| XYZ Guiding Rails | Taiwan PMI 30mm | Taiwan PMI 30mm | Taiwan PMI 30mm |

| Machining Accuracy | <0.03/300 mm | <0.03/300 mm | <0.03/300 mm |

| Maxi Working Speed | 24,000 mm/min | 24,000 mm/min | 24,000 mm/min |

| Spindle Speed | 6000–36000 rpm | 6000–36000 rpm | 6000–36000 rpm |

| Controller | Syntec ATC (optional NC Studio) | Syntec ATC (optional NC Studio) | Syntec ATC (optional NC Studio) |

| Format of Instructions | G Code or HPGL | G Code or HPGL | G Code or HPGL |

| Voltage | AC 380V/60Hz | AC 380V/60Hz | AC 380V/60Hz |

| Net Weight | 2000 kg | 2800 kg | 3200 kg |

| Packing Size | 3860 x 2230 x 1900 mm (17 CBM) | 4200 x 2230 x 1900 mm (18 CBM) | 4200 x 2230 x 1900 mm (18 CBM) |

**Machine Details:**

1. **Base Frame:** Heavy-duty tubular steel, machined by gantry milling and stress-relieved for long-term stability.

2. **ATC Spindle:** Air-cooled, high-reliability HSD spindle with programmable speeds up to 24,000 RPM.

3. **Tool Station:** 8-position station for easy loading/unloading.

4. **Controller:** Taiwan Syntec industry controller with USB support and power failure protection.

5. **Servo Motor:** High-power Panasonic motor with planetary gearbox for smooth and efficient cutting.

6. **Gear Rack & Rails:** High-precision gear rack on XY axis, ball screw on Z axis, and 25mm Hiwin square rails for rigidity.

7. **Vacuum Table:** Multi-zoned design for flexible material handling.

8. **Lubrication System:** Central oil lubricator for regular maintenance.

9. **Design Software:** Compatible with Type3, UcancamV10, Artcam, etc., for G-code generation.

**Our Values & Commitment:**

- Business with integrity, no deception.

- Quality products and premium service.

- Support for distributors and end users.

- Continuous improvement and innovation.

**Quality Control:**

- Strict quality checks during procurement and production.

- Final testing before shipment with photos and videos provided.

**Warranty:**

- 2-year warranty on the whole machine; lifetime maintenance.

- Free replacement of faulty parts within warranty period.

- Free repair for out-of-warranty parts.

- Customer covers shipping costs.

**After-Sale Service:**

- Long-term spare parts supply and free lifetime maintenance.

- 24/7 online technical support via phone, email, WhatsApp, etc.

- Free training at our factory.

- Paid on-site installation and training.

- Regular follow-ups to ensure service quality.

**Company Introduction:**

WILLIAM INTERNATIONAL is a Chinese manufacturer of CNC routers, label cutters, flatbed cutters, laser marking machines, and cutting plotters. Our brand, VICUT, focuses on providing cost-effective, high-quality solutions for overseas markets.

**Market:**

We operate in North America, South America, Europe, Oceania, Middle East, Southeast Asia, South Asia, and West Asia. We are always looking for new partners to grow together.

**Products:**

We offer a wide range of CNC engraving and cutting machines, including custom options for shape, size, color, and structure. OEM is available.

**Team:**

We have two workshops in Hefei, Anhui, with over 200 employees. Our R&D team continuously improves product designs to meet market needs.

**Contact Us:**

If you need more information, feel free to contact us.

**Contact Person:** Max Luo

**Cell:** +86 17756014359