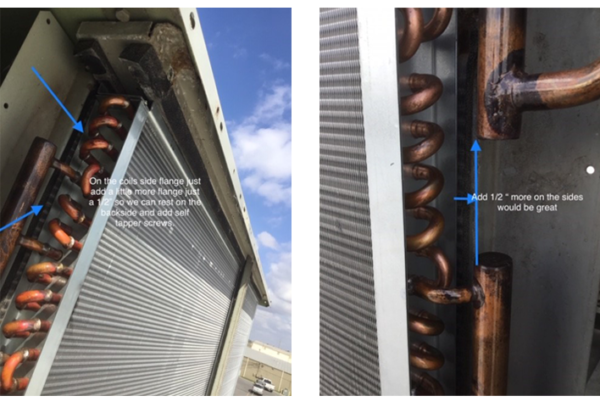

Nationwide Coils completes another on-site microchannel conversion for a major telecom client. Recently, we completed another successful microchannel conversion at a large telecom facility in South Texas. This time, we worked on a Trane TCD600B unit that originally featured eight all-aluminum MCHX coils. The goal was to improve performance and reliability by upgrading the system. Instead of replacing the existing coils one by one, we designed two larger copper tube, aluminum fin coils. This made installation more efficient and simplified the process for the field team. The new coils not only offer better durability but also improved heat transfer efficiency compared to the original aluminum setup. The installation went smoothly, and the customer was able to reposition the new coils with minimal adjustments. Each coil is over 5 feet tall, 6 feet wide, and weighs around 175 pounds—so they’re definitely built to last. Because of the success of this project, the client has since reached out to us to convert their additional Trane RTUs on a quarterly basis. They’ve also requested a small modification: increasing the end plate flange length from 1" to 1.5". This will allow them to secure the casing using self-tapping screws more effectively. The client shared some great photos of the installed coils and provided detailed notes for future units. As the saying goes, a picture is worth a thousand words—and these images tell a clear story of quality work and customer satisfaction. At Nationwide Coils, we pride ourselves on being experts in MCHX conversions, and our ability to customize commercial HVAC coils makes us a trusted partner for OEM replacements and upgrades. Unlike many OEMs, we can tailor each coil to fit your specific needs and make installations easier and more efficient. If you're dealing with common issues like leaks or inefficiencies in your current microchannel coils, consider switching to a copper tube, aluminum fin design. This upgrade offers long-term reliability, easier maintenance, and maintains the same level of efficiency as the original OEM unit. Ready to learn more about MCHX conversions? Contact us today—just provide the unit's make and model, and we'll get started right away. - PVC coated Stainless Steel Wire Rope: This type of wire rope is coated with a layer of PVC (polyvinyl chloride) material, which provides protection against corrosion, abrasion, and weathering. It is commonly used in outdoor applications, such as marine, fishing, and construction industries. nylon coated stainless steel wire rope,coated stainless steel wire rope,pvc coated stainless steel wire rope Jiangsu Juke Metal Products Co.,Ltd. , https://www.jsjukemetal.comSITE BITE: Converting the Microchannel in a Trane® TCD600B Unit

Before: Trane unit with eight all-aluminum microchannel coils.

After: Our two copper tube, aluminum fin coils installed.

Written by: Stephen Barzelatto

Vice President, Nationwide Coils

- Nylon coated Stainless Steel Wire rope: This type of wire rope is coated with a layer of nylon material, which provides additional resistance to abrasion, chemicals, and UV rays. It is commonly used in indoor applications, such as gym equipment, garage doors, and industrial machinery.

- Coated stainless steel wire rope: This refers to any type of wire rope that has been coated with a layer of material (such as PVC, nylon, or polypropylene) to enhance its durability, flexibility, and appearance. Coated wire ropes are often used in applications that require high strength, low stretch, and resistance to wear and tear.